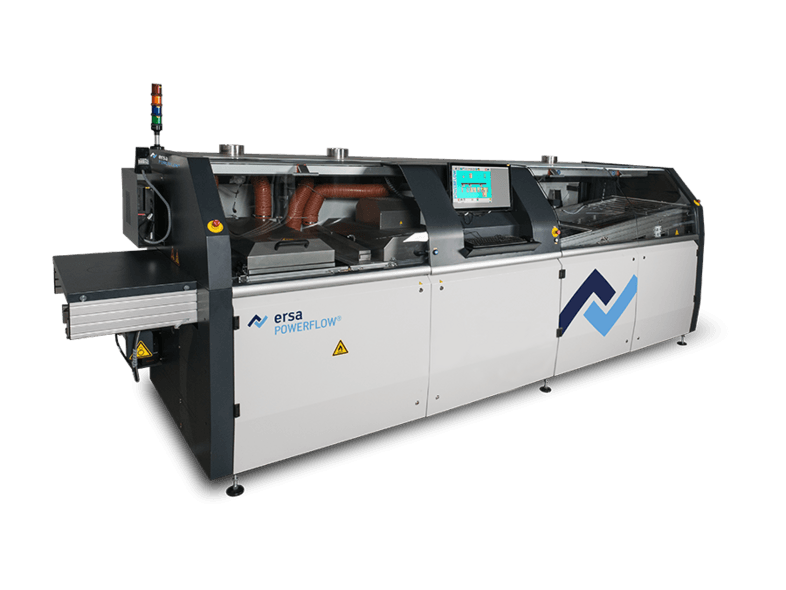

Ersa POWERFLOW Wave Soldering Systems for High-Performance PCB Assembly

Ersa POWERFLOW wave soldering systems are engineered to meet diverse customer requirements, ranging from high-end full-tunnel inert gas soldering systems to open atmospheric wave soldering systems. Designed for modern wave soldering applications with formats up to 610 × 850 mm, these systems offer stable processes and reproducible parameters, ensuring exceptional availability, economy, and quality.

Key Features:

Versatile Soldering Solutions: Tailor your wave soldering process with systems that adapt to both high-end inert gas soldering and open atmospheric wave soldering, providing flexibility for a wide range of applications.

Stable and Reproducible Processes: Rely on consistent, stable processes and parameters that deliver reliable results, making it easy to master any wave soldering task efficiently and effectively.

Powerful Performance: Benefit from a powerful wave soldering system that offers an impressive price/performance ratio, ensuring cost-effective production without compromising on quality.

Modular and Flexible Preheating: Customize your preheating process with a modular and flexible preheating concept that can be configured variably in terms of length and output, and can even be retrofitted to meet evolving needs.

Comprehensive Monitoring and Documentation: Keep track of all process-relevant data with advanced monitoring and documentation capabilities, ensuring your wave soldering process is always ready for traceability.

Ersa POWERFLOW wave soldering systems provide the flexibility, power, and reliability needed to excel in modern PCB assembly. With the ability to configure and expand based on specific requirements, these systems are the ideal choice for achieving high-quality wave soldering results in a cost-effective manner.