Optimize Your PCB Manufacturing with Precise SMT Temperature and Humidity Control

In the intricate world of PCB manufacturing, maintaining strict control over temperature and humidity is crucial. The right environmental conditions on the manufacturing floor can make all the difference between producing flawless PCBs and encountering costly defects. This article delves into the significance of temperature and relative humidity (Rh) control in PCB assembly and offers insights into achieving precision in your operations.

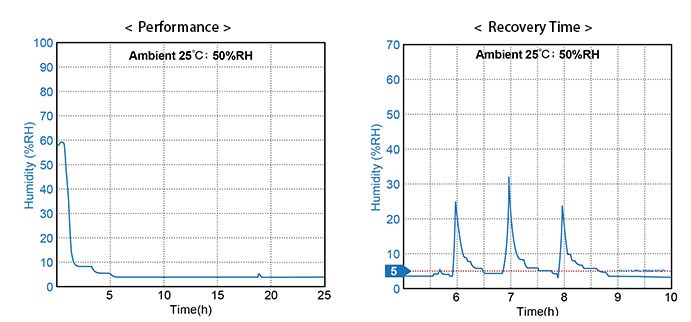

The F1 dry cabinet is a cutting-edge solution designed to maintain an internal humidity level as low as 1% RH. This makes it the ideal choice for moisture-proof and anti-oxidation storage applications. Whether you're storing precision metal parts, miniature devices, pharmaceutical substances, biotic specimens, batteries, crystals, IC package modules, optical lenses, MSD, MBB, or scientific precision instruments, the F1 dry cabinet offers unparalleled protection against corrosion, mold, and deterioration.

iX2B is specially designed for moisture sensitive devices of level 4,5,5A,or 6. The iX2B can eliminate oxidation of stored parts. So it is useful for storing parts such as precision metal parts, miniature devices, pharmaceutical substance, biotic specimens, battery, crystal, IC package module, optical lens or scientific precision instruments..etc.

Additionally, our customized dry box services cater to specific storage needs, including Tape Feeder Cabinets and Tape Reel Storage Cabinets, ensuring that every component of your PCB assembly process is stored under optimal conditions.

Ensure the longevity and reliability of your sensitive materials with our state-of-the-art storage solutions, designed to meet the rigorous demands of modern PCB manufacturing.